Optimisation of the soldering process in power electronics

Efficient conversion thanks to customised tacky gel

The Amberg equipment plant of Siemens AG faced a special challenge in the area of power electronics production: preforms (solder plates) are precisely positioned using solder frames as standard. Due to process optimisation, it was necessary to find an alternative without the use of solder frames in order to reliably fix components and simplify the soldering process.

Stannol was able to support the company with a specially developed tacky gel. Volker Schmidt, who works in the "Smart Infrastructure" and "Process Engineering Technology" departments at Siemens AG, explains the challenges that had to be overcome during the changeover.

Optimisation of the soldering process

In the module series in question, chips are soldered onto direct copper bonds (DCBs). These consist of a lower copper layer, an aluminum oxide ceramic in the middle and another copper layer on top. Components such as thyristors or silicon carbide MOSFETs are then soldered onto this top copper layer.

"The soldering process is a No-Clean process, which means that subsequent cleaning of the DCBs is not necessary. The prerequisite for this is that no measurable residues remain on the DCBs after soldering to ensure the reliability and electrical function of the assemblies," emphasises Volker Schmidt.

Tests with new tacky gels

The company evaluated various options and processes for this. Volker Schmidt: "It was important to us that the future process would guarantee an absolutely clean solder joint, as bonding wires would be placed afterwards and applied using an ultrasonic joining process. To achieve this, the solder joint must be flawless and without any measurable residue."

Traditionally, cost-intensive graphite frames could have been used, which are placed on the component and ensure that there is no rotation or misalignment of the component, but this would have required high investments. The use of solder pastes without activators also proved to be unsuitable for the existing equipment in tests due to high condensate residues.

"Another idea was then to use a tacky gel to ensure that the components stay in place – even without a graphite frame." Overall, Siemens carried out tests with various tacky gels, including the new tacky gel TG6000 developed by Stannol.

Requirements for the tacky gel

- reliable fixing of the components until they enter the vacuum soldering system

- no gas inclusions in the solder (voids)

- no visible or measurable residues after heating up

Development of the tacky gel TG6000

The new tacky gel TG6000 is based on the flux system of the Stannol solder paste SP6000. "We received a request for a flux gel that does not contain activators, explains Dr. Sven Mönninghoff, Head of Research and Development at Stannol.

"We then modified the existing solder paste flux M6000 by making specific adjustments to the recipe in order to meet the required specifications of the TG6000. In addition, the manufacturing process was fine-tuned to ensure optimum production and the required properties of the TG6000," says Mönninghoff.

Comprehensive analyses and test cycles

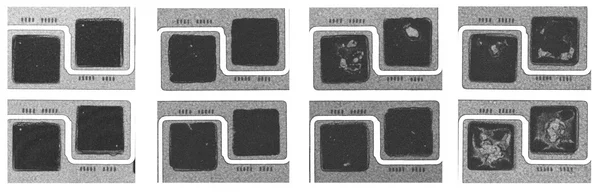

Various tests and analyses were carried out at Siemens as part of extensive material technology investigations. First of all, micrographs were taken of the joints to check the quality of the soldered connections between the chips and the assembled components. The reaction of the material with the potting compound used was then examined.

In addition, device tests were also carried out, in particular power cycle tests, in which the assemblies are connected to a load and subjected to several cycles. These tests simulate extreme switching operations in order to examine the behaviour of the component under constant load changes. The required number of cycles was achieved.

No measurable residues, minimal voids

It was also checked whether residues of the tacky gel remain on the copper after the soldering process. For this purpose, tests were carried out in which the tacky gel was applied to the bare copper surface. A process without components was then carried out. In the infrared examination of the copper surface, no measurable residues could be detected on the copper surface.

However, the more critical area lies in the layer structure of the "sandwich", which consists of the copper surface, tacky gel, solder preform and finally the chip. Volker Schmidt: "As the reaction gases cannot escape so easily from this structure into the atmosphere, but have to be removed under the chips and the preform by vacuum, this area was examined particularly closely. No measurable residues could be detected here either. It can therefore be virtually ruled out that reactions with the silicone potting will occur."

Particular attention was also paid to the formation of bubbles under the potting, as this could be an indication of a possible chemical reaction. However, no bubble formation was detected. "Following the positive test results, we have approval to use TG6000 in our manufacturing process," says the expert.

Changeover brings advantages

The change to the process has several advantages for the company: "With the new option of sourcing solder and tacky gel separately, we can react more quickly to changes, such as adjustments to the quantities of solder or tacky gel. In future, we will be able to adjust the shape and thickness of the preforms as well as the quantities of tacky gel, making us more flexible in production," emphasises Schmidt. He also sees potential for the demand for TG6000 to rise in the future – particularly in the fields of electromobility and energy conversion.

The growing demand for inverters, electric drives and similar applications could increase the quantities for power electronics products, as these electrical components are slowly replacing electromechanical components. "A key advantage of our product is that we operate within a standardised flux system. Whether it is the solder paste SP6000 or the tacky gel TG6000 – all components are based on the same chemistry. This ensures complete compatibility, which can also be a decisive advantage for rework processes or other adjustments in the future," emphasises Dr. Sven Mönninghoff.

Close and open communication between customers and suppliers is crucial in order to overcome technical challenges quickly. In the case of Siemens AG, the direct exchange with Stannol enabled the rapid development of a customised tacky gel, whereby the production process was efficiently adapted, risks minimised and the highest quality standards ensured.

Author