Professional tests from our laboratory

We offer a comprehensive testing and analysis service through our in-house laboratory.

This includes not only careful execution of the tests, but also detailed evaluation and documentation of the results. If you need a service that is not listed, please contact us – we will be happy to provide you with an individual offer.

Solder bath and metal analyses

You would like to subject your solder bath to a routine check or have the impression that your solder bath is contaminated or the soldering results have deteriorated? Our solder bath analysis provides you with reliable information about the quality of your solder bath: Our laboratory is equipped with modern spark spectrometers that analyze your solder bath samples and check them for composition or possible impurities.

We perform the solder bath analyses for our customers free of charge during the adaptation process. For non-customers who wish to use our service, this is subject to a charge. With our experienced team of application engineers, we are also happy to support you in defining specific intervention limits.

Further information on taking the solder bath sample, marking the sample and filling out the sample submission form can be found in the following PDF documents.

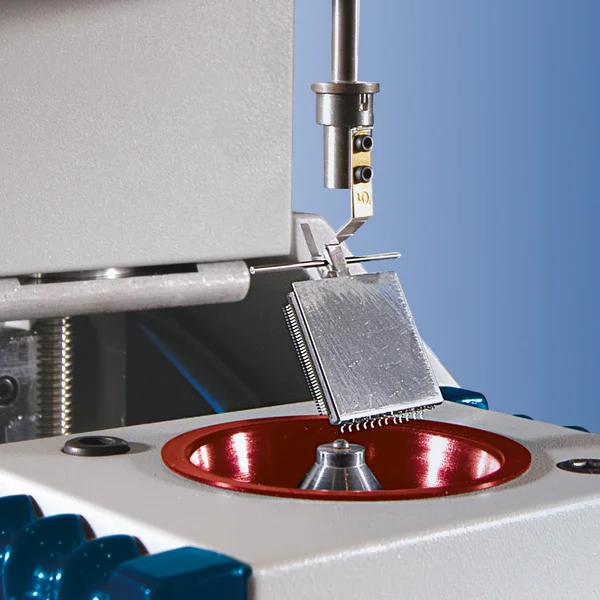

Wetting tests and solderability tests

Poor solderability is one of the most common causes of defects in a soldering process. Therefore, it makes sense to test the solderability of components or PCBs in advance.

We carry out solderability tests on SMD components, wired components, printed circuit boards and substrates for you according to the common standards of IEC and IPC. For this purpose we use the wetting balances MUST System 3 from GEN3 Systems. This allows the wetting process to be quantified. The wetting forces are recorded and the test process is documented on video.

Your advantages

- Minimisation of soldering errors in production

- Micro wetting scale test for small or multi-pole components

- Step & repeat function for multi-pole components

More info on the MUST 3 System Wetting balance test procedure

Inspection of printed circuit boards and assemblies for ionic contamination

Electrically conductive contaminations on printed circuit boards and assemblies are a major problem – especially in the context of the increasing miniaturisation of all components. With the help of our Contaminometer CM11+ and CM33 from GEN3 Systems, we can reliably check your PCBs and assemblies for ionic contamination.

Your advantages

- Measurement of ionic impurities in accordance with international standards:

IPC-TM-650 2.3.25 (ROSE Testing), IEC 61189-5-504 (PICT Testing) - Highly accurate measuring system

- Different tank sizes for different PCB sizes

Available versions

| Designation | Tank size |

| CM11+ | 300 x 250 x 36 mm |

| CM33 | 500 x 350 x 60 mm |

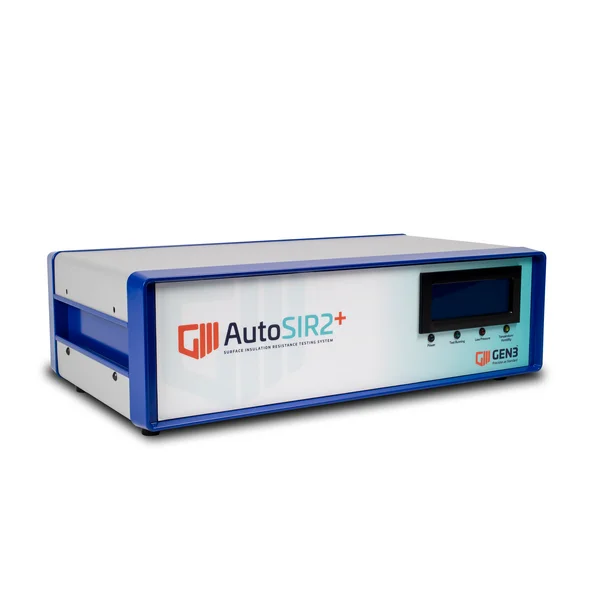

Surface insulation resistance measurement (SIR test)

Our laboratory offers you the opportunity to have professional SIR tests carried out. These tests provide valuable insights into the electrochemical behaviour of your process materials - especially around the compatibility of different solders and coatings used in a soldering process.

Our state-of-the-art equipment, such as the latest generation GEN3 AutoSIR2+ and the climate chamber from weisstechnik®, ensures precise and reliable measurements that are performed in accordance with current standards. With the AutoSIR2+, we are able to realise measurement setups with up to 128 channels.

Your advantages

- Tests in accordance with IPC J-STD-004C (SIR and ECM)

- 16 test combs per rack for a larger test field

- Extended test scenarios for added security

More information on AutoSIR 2+

If you have any questions, please contact