SP6000 TBS04

The sustainable solution for sensitive electronics

The demands placed on modern electronic assemblies are increasing – and with them the need for gentle, energy-efficient soldering processes, because

- less thermal stress protects sensitive PCBs and extends the service life of your assemblies.

- lower process temperatures mean lower energy consumption, lower costs, reduced system wear and greater sustainability.

The solution: SP6000 TBS04 from Stannol

With SP6000 TBS04, Stannol presents an innovative No-Clean LMPA solder paste that has been specially developed for applications with reduced peak temperatures in the reflow process, such as in the field of LED technology or optoelectronics.

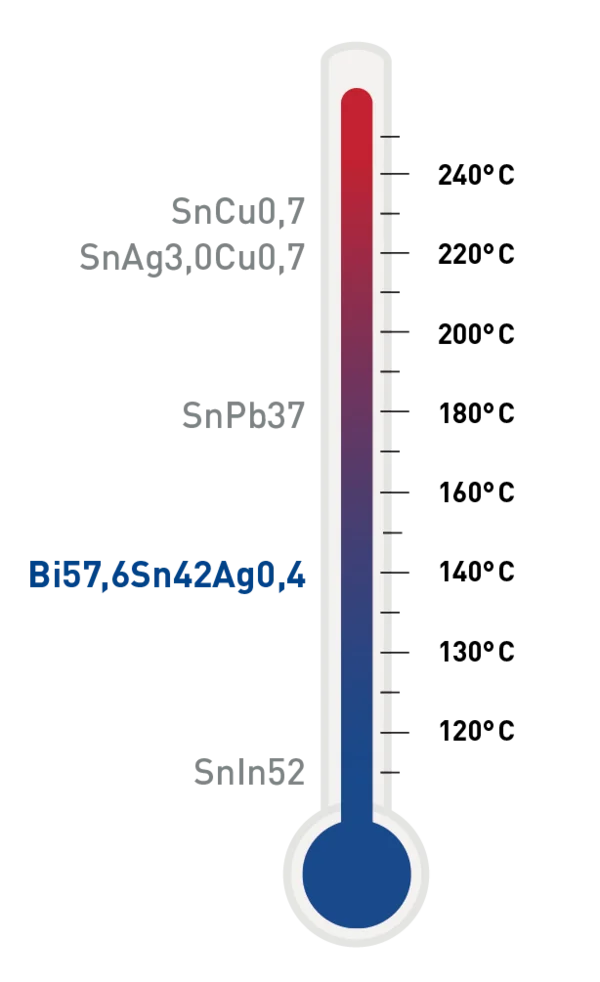

Based on the alloy Bi57.6Sn42Ag0.4 , the BSA solder paste combines technical performance and sustainability in one product.

Graphic: Stannol Bi57.6Sn42Ag0.4 compared to other common alloys.

Your advantages at a glance

- Low melting range (~140 °C): ideal for temperature-sensitive components – with a maximum reflow temperature of only 170-180 °C

- Solder powder made from recycled material: for over 85% CO₂ savings – sustainable soldering has never been so easy

- Lower system wear & energy consumption: reduced process temperature measurably reduces your operating costs

- High long-term reliability: significantly more durable than pure BiSn alloys thanks to silver content (0.4 %)

- Fine precision: suitable for fine-pitch applications down to 0.4 mm – perfect results even with miniature components

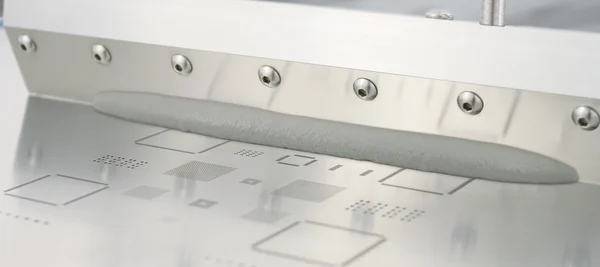

- Process stability: very good contact pressure behavior even after longer printing breaks

- Flexible use in the reflow process: under air or nitrogen

- Excellent wetting properties: can be used on a wide range of common surfaces

- Naturally RoHS-compliant

Who is SP6000 TBS04 suitable for?

The BSA solder paste SP6000 TBS04 is the ideal solution for developers and manufacturers who:

- need to process sensitive electronic components safely and gently.

- work in optoelectronic and LED applications with limited thermal load capacity.

- want to reduce their production costs but do not want to compromise on quality and reliability.

- want to make a contribution to greater sustainability in electronics production.

Superior Technology. Sustainable by design.

Made by Stannol.

With the SP6000 TBS04, you are not only opting for a high-performance solder paste – but also for a forward-looking solution that harmonizes economic and ecological requirements.

More possibilities – thanks to precise dosing.

SP6000D TBS04.

SP6000 TBS04 is also available on request as a dosable version (SP6000D TBS04).

Find out more now and contact our expert