Stannol Smart 4D Thermal Profiler

No more invisible errors: Ensure that every soldering profile is perfect

The Smart 4D Thermal Profiler was developed to eliminate uncertainties during soldering. In modern soldering processes, precise temperature control is crucial to reliably achieve good solder joints and avoid failures. The profiler measures and analyses the temperature curves directly on the assembly so that problems can be detected early and processes can be optimally adjusted.

Your advantages

- Real 4D Profiling: captures temperature (at the sensors), system temperature (via pyrometer), vibration measurements in XYZ (via accelerometers), and time

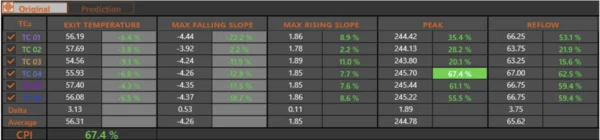

- Fast and precise temperature measurement: directly on the assembly for maximum process control

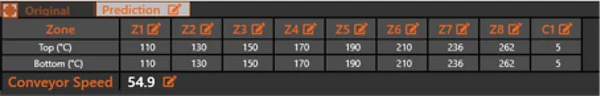

- Prevention of soldering defects: through precise analysis and software-supported optimization of the soldering profile

- Easy operation and intuitive software: with real-time data and clear evaluations

- Improved system control: temperature and vibration measurements enable early detection of technical issues

- Component-specific optimization: fine-tuning of the soldering profile considering different component requirements

- Universally applicable: suitable for various oven types and soldering applications

Optimise your soldering process now - with precise 4D temperature monitoring

Support in four dimensions

The Stannol Smart 4D Thermal Profiler offers you an innovative 4D solution that analyses other important parameters in addition to the classic recording of a temperature profile.

The four dimensions:

- Temperature at the temperature sensors: Get precise readings directly at the crucial points of your assembly.

- Vibration measurement: Measure the vibrations in your system using advanced acceleration sensors (in the X, Y and Z directions) to detect changes in system behaviour at an early stage before they affect the process.

- Equipment temperature: Use pyrometer technology to monitor the temperature of the soldering equipment itself and ensure that it remains within optimal operating parameters.

- Time: View and analyse the evolution over time of the aforementioned dimensions.

Highly functional software

The Stannol Smart 4D Thermal Profiler software offers a wide range of functions that further improve your monitoring and analysis:

- Selection of soldering systems:

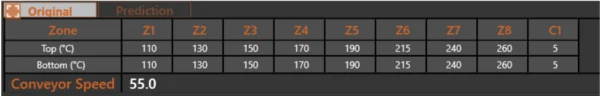

Many common soldering systems can be selected in the software to enable flexible customisation to your specific requirements.

- Live data readout:

The measurement results can be viewed during the measurement process thanks to the Wi-Fi functions.

- Solder paste management:

Define and select different solder pastes to ensure the right materials are used for your applications.

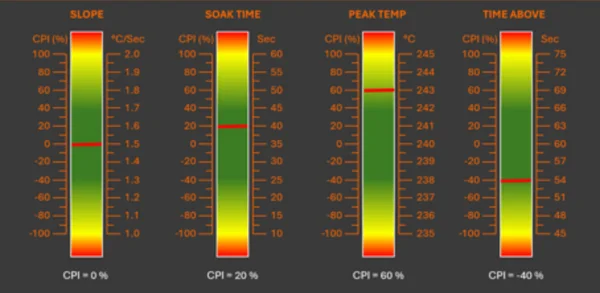

- Process windows:

Define process windows to control the temperature profile. Critical Process Indicators (CPIs) are defined within these windows, which define a target range and an exact target value (e.g. time above melting temperature: 30-60 seconds, target value 45 seconds).

Properties

- 6 measuring channels for temperature sensors (type K)

- 2 pyrometers for system monitoring

- Acceleration sensors (XYZ) for vibration measurement

- Software with analysis and optimisation function

- Rechargeable via USB-C connection

Specification/technical data

| Internal operating temperatures | -0 °C to 75 °C |

| Accuracy | +/- 0.5 °C |

| Resolution | 0.1 °C |

| Measurement rate | 0.1 to 50 readings per second |

| Temperature range | -250 °C to 1200 °C |

| Wi-Fi | 2.4 GHz |

| Measuring inputs | 6 channels, K type, standard |

| Acceleration sensors | 1 x X-axis, 1 x Y-axis, 1 x Z-axis |

| Pyrometer | 2 |

| LEDs for battery status | 4 |

| Device status LEDs | 4 |

| Dimensions L x W x H mm | |

| Device dimensions | 120 x 65.5 x 14.5 mm |

| Protective box steel dimensions | 281 x 78 x 24 mm |

| Protective box with insulation dimensions | 281 x 80.5 x 27.5 mm |

| Internal power supply | 2 x AAA Ni-MH batteries rechargeable via USB-C |

We are happy to support you

If you have any questions or would like an individual solution, our expert Nicolas Wiacker will be happy to support you.

CPU: 1 Ghz or faster with 2 or more cores.

Memory: 4GB RAM

Hard drive: 64 GB or more

Ports: 1 or more USB type A ports

Operating system: Operating system: Microsoft® Windows® 10 newer

- Stannol 4D Smart Profiler

- USB Wi-Fi dongle

- Temperature protection box

- Transport case

- Carrier for the device (carrier)

- USB-C to USB-C cable or USB-A to USB-C cable

- Protective gloves

- 6 type K thermocouples

- Scissors

- 6x aluminium adhesive strips

- Digital user manual

- 2 year warranty (excluding batteries)