Excellent Alloy Systems

Precisely tailored solutions for demanding soldering processes

Stannol is an official licensee of the Nihon Superior alloys SN100C®, SN100Ce®, SN100CV® and SN100CVe®.

These high-quality, globally established solder alloys stand for excellent processability, high process stability, reliability and cost-effectiveness in electronics production.

All alloys are silver and lead-free and are particularly suitable for applications with the highest quality and reliability requirements.

SN100C® and SN100Ce®

Process-stable tin-copper-nickel alloys

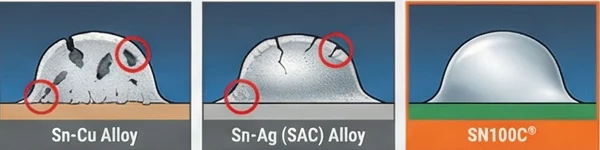

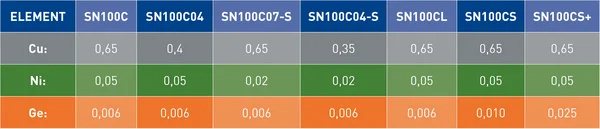

The SN100C® alloy (SnCu0.7Ni) uses nickel as a micro-alloying element to reduce copper enrichment in the solder bath, thus enabling stable and reproducible process control. Germanium significantly reduces dross formation and thus helps to conserve resources and protect the environment. At the same time, nickel in combination with tin and copper ensures a finer intermetallic phase, which increases the mechanical stability of the solder joints.

SN100C® is also characterised by very good wetting properties and reduced bridging.

The alloy is supplemented by SN100Ce® – the suitable post-soldering alloy for process stabilisation in order to keep the solder bath in the long-term optimum composition.

Product Features SN100C®

- patented, micro-alloyed, eutectic alloy (melting point: 227 °C)

- reduced leaching rate compared to the S-Sn99.3Cu0.7 alloy

- reduced dross formation compared to the S-Sn99.3Cu0.7 alloy

- reduced bridging and icicle formation

- shiny, homogeneous solder joints

- silver- and lead-free

- suitable for wave and selective soldering systems

Physical Data

SN100CV® and SN100CVe®

High-performance alloys with increased fatigue strength

The bismuth-doped alloy SN100CV® (SnBi1.5Cu0.7Ni) is based on a nickel-stabilised tin-copper solder and also contains germanium to significantly reduce dross formation. It is ideal for applications with particularly high quality and reliability requirements.

Thanks to the bismuth content, SN100CV® achieves around 30 percent higher fatigue strength compared to SN100C® and thus even exceeds the performance of SAC305. At the same time, the already low copper alloying of SN100C® is further reduced. The result is stable processes and particularly simple process management.

For long-term stabilisation of the solder bath, SN100CVe® is available as a suitable refill alloy.

Product Features SN100CV®

- bismuth-doped, patented high-performance alloy

- reduced dross formation due to germanium

- approx. 30 percent higher fatigue strength compared to SN100C® – more powerful than SAC305

- further reduced copper dissolution for stable, easy-to-control processes

- silver-free and lead-free

suitable for wave and selective soldering systems

Availability

Nihon Superior alloys are available from Stannol in the following forms:

- solder wire (solid and flux-cored)

- triangular bars

- kilobars

- ingots with hanger hole

- pellets (approx. Ø 5 mm × 30-35 mm)

Contact Person