Digitised storage of solder pastes

When handling temperature-sensitive solder pastes, there are a number of things to consider in everyday production. In order to simplify the professional storage and management of the products, companies can rely on a digitalised solution: As part of Industry 4.0 concepts, innovative cooling devices ensure that, in addition to monitoring the temperature of the stored solder pastes, a controlled supply of materials is also guaranteed.

W. Kolb Fertigungstechnik GmbH from Willich has been using a Smart Warehouse from Stannol since August 2022. Tobias Bach, Technical Manager SMT and responsible for automatic optical inspection (AOI) at Kolb, explains the advantages of digitised storage.

Better management of customer audits

To ensure that solder pastes can be processed properly, some standards must be taken into account during handling. For example, depending on the product, refrigerated storage between 2 °C and 8 °C must be ensured. For processing, solder pastes should be tempered to 25 °C in advance – a higher temperature should again be avoided. In addition, solder pastes have a relatively short shelf life of around six months. For Tobias Bach, the decision to store and manage the required solder pastes digitally was an easy one, because: During customer audits, questions are also frequently asked around the topic of handling solder pastes in operations, such as: "How can it be ensured that no solder pastes are used that have already expired?" or "How is it ensured that the removal time is correctly recorded?" "It has been difficult to answer these questions satisfactorily because manual handling is difficult to prove and trace. This was a weak point that we were able to eliminate with the Smart Warehouse," the expert reports.

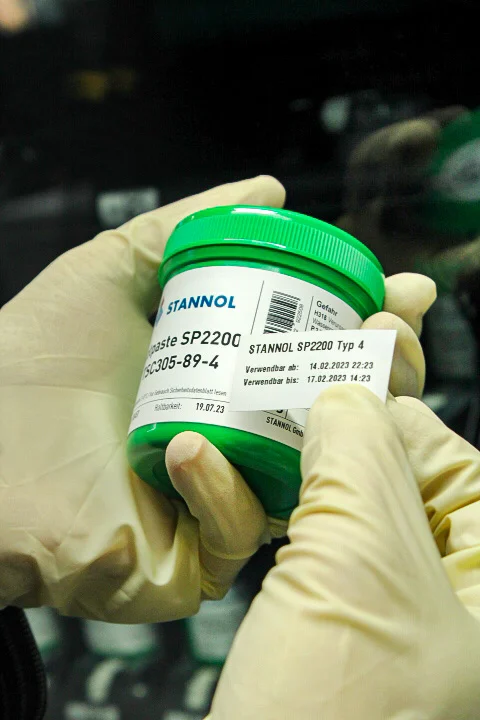

Recording withdrawal and consumption time

At Kolb, the cooling unit is currently used to store two different solder pastes. When a solder paste is removed at the push of a button, a label is automatically printed that records both the removal time and the consumption time. "After removal from the refrigerator, the solder pastes are ready for use after eight to twelve hours. This time is stated on the label. This is unambiguous and clearly verifiable at any time," Tobias Bach emphasises. The same applies to the consumption time, that is, the time within which the paste can be used before it becomes too dry, for example.

Simple removal according to FIFO principle

Another advantage: according to the "first-in-first-out" principle, the materials that have already been stored the longest are automatically given out first. This ensures that less material exceeds the expiry date. Alternatively, after appropriate programming, the output can also take place according to the respective expiry date. In this case, the products with the shortest shelf life are delivered first. If stored materials are close to expiry, the device can also issue a warning. Tobias Bach: "The handling of the device is simple and almost intuitive. It could be integrated into the running operation without any problems and has been well accepted by the users here at Kolb."

Automated ordering

The individual compartments of the Smart Warehouse are provided with barcodes. When filling with new solder pastes, both this barcode and the article numbers of the filled products are scanned and the corresponding data is stored in the device. In this way, it is directly visible where which product is located, how much of which material is still available or how long the solder pastes can be stored. If the filling level of a product falls below a defined minimum quantity, the device can trigger an automatic order. "In our case, this happens automatically by e-mail. We are still working on the finer points, such as when is the right time to initiate an order, for example, if you have to take certain delivery times for different products into account," explains Bach.

Monitored cooling process

The cooling of the contents is permanently monitored and the temperature curve is recorded. In this way, temperature profiles can also be created retrospectively or individual data for a specific product and time can be retrieved. "Here, for example, we can prove in audits that product x was stored at temperature z on day y. This gives us great confidence in our actions – and ultimately also convinces our customers when it comes to quality assurance," Tobias Bach emphasises.

Personalised output

The Smart Warehouse offers even more options. For example, the output of different products can be restricted or defined to certain persons. "This makes sense if you want to minimise the risk of confusion, for example with leaded and lead-free solders or solder pastes of different alloys and grain sizes," explains Thomas Kolossa, Head of Sales at Stannol. For the expert, companies can hardly avoid professional digitalised storage – especially in times of a shortage of qualified professionals, when it is also a matter of supporting the existing staff in the best possible way with work-saving measures. Tobias Bach: "For us, digital storage is a really smart solution. It saves time, resources and ensures an error-free process that can also be tracked seamlessly. We will expand the possibilities offered by the device even further in the future.

About Kolb

W. Kolb Fertigungstechnik GmbH has already been a permanent member of Stannol's customer base since 2019.

The Willich-based company with around 210 employees has been manufacturing electronic assemblies for customers from a wide range of industries for around 30 years.

In 2022, Kolb switched its entire THT production to Stannol's sustainable greenconnect product range.

Smart Warehouse – Key Facts

- material output as required

- GSM Internet module

- traceability

- temperature control and monitoring

- first-in-first-out material dispensing

- flexible interior design, can be adapted to different materials

- personalised, controlled material output

- minimum quantity definable

- label configurable

- integrated label printer

Author